Flow back equipment

Why Debris Catcher is used during flowback and well test operations?

_%E5%89%AF%E6%9C%AC.png)

After hydraulic fracturing, debris/trash will come from the well, which needs to be removed. Flowback equipment deploy several sets of flowback equipment, such as debris catchers, sand traps, sand separators, choke manifolds, high-stage, and low-stage separators, as well as other auxiliary equipment. So, debris catchers are highly effective in bulk removal of debris coming from the well. Debris catchers come in different configurations and skid structures. Rein Wellhead Equipment is API-certified company in China, which designs and fabricates various types of debris catchers and other solid-control equipment in China.

Debris/Trash Catcher is used during well clean-up, flowback and surface well test operations.

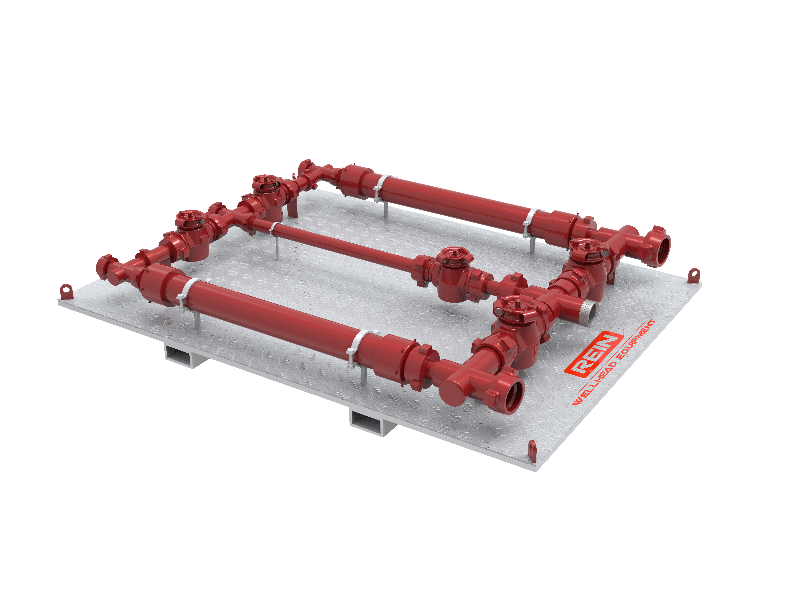

Debris Catcher Plug Valve Manifold is a special type of oilfield manifolds designed to catch debris/trash from well stream during flowback operations. Debris Catcher Manifold consists of several plug valves or slab gate valves, catcher-cylinder, high-pressure fittings, and pressure gauge.

Pressure rating of Debris Catcher Plug Valve Manifold

MPa | 35 | 70 | 105 |

psi | 5000 | 10000 | 15000 |

Sizing of Debris Catcher Plug Valve Manifold

Inlet Connection | 2” Fig.1502, 3” Fig.1502, API Flange 3.1/16”-10K/15K, API Flange 4.1/16”-10K/15K, API Flange 5.1/8”-5K, |

Outlet Connection | 2” Fig.1502, 3” Fig.1502, API Flange 3.1/16”-10K/15K, API Flange 4.1/16”-10K/15K, API Flange 5.1/8”-5K, |

Catcher Barrel Sizing

In. | 3 | 4 | 5 | 6 | 7 |

Code & Standards

API 6A |

NACE MR-0175 |

ISO 15156-1, -2 |

ASME B31.3 |

PED 97/23/EC |